Fresh Water Generator on Ships: Complete Guide for UAE Marine Operators, Working Process, System Setup, and Best Practices

Fresh water is the lifeline of every vessel. No matter if it is a cargo ship crossing the Arabian Sea, an offshore support vessel working near Abu Dhabi, or a passenger craft cruising through Dubai waters, every ship needs a reliable way to produce clean fresh water during long voyages.

Most vessels in the UAE region rely on a Fresh Water Generator, often called FWG, which converts seawater into usable water for drinking, cooking, sanitation, and machinery needs. This guide explains the full working principle, components, operating steps, maintenance, and common issues in a simple and human style.

This blog is created for marine engineers, ship operators, purchasing teams, and technical superintendents in the UAE who want a practical and easy to understand breakdown, along with insights on how Amazon Blu Ship Supplies supports reliable fresh water systems onboard.

What Is a Fresh Water Generator on a Ship? (Simple Definition)

A fresh water generator is a system that converts seawater into fresh drinking water by using heat and vacuum. Most ships use the heat from the main engine jacket water to evaporate seawater at a lower temperature, then the vapor is cooled to produce clean water.

This process is also called the evaporation method, and it is the most widely used setup on merchant ships in the Middle East.

Passenger vessels sometimes use reverse osmosis systems, although these systems usually have higher cost and more maintenance.

Why Ships in the UAE Need a Fresh Water Generator

Ships operating around the UAE often sail in hot climates, so water consumption is naturally higher. Long voyages, crew size, engine cooling needs and limited storage space make onboard water production very important. Buying water in bulk from ports like Fujairah and Jebel Ali is possible, but it adds cost and storage challenges.

So an FWG becomes the most economical choice for:

- Crew drinking water

- Cooking and galley operations

- Showers and sanitation systems

- Cleaning machinery and decks

- Cooling water for equipment

- Emergency needs including firefighting

A stable fresh water generator keeps the vessel self reliant, which is valuable for fleet operators in the UAE.

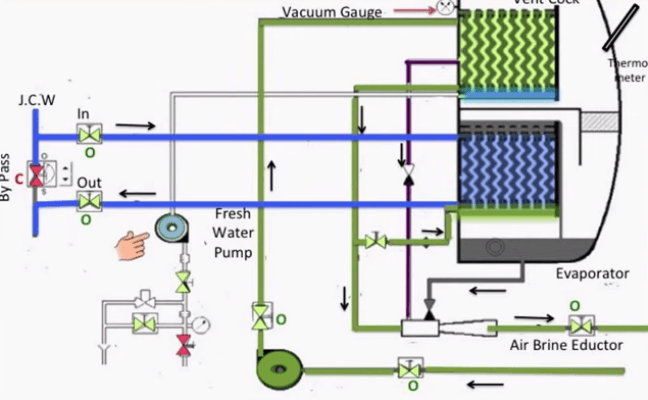

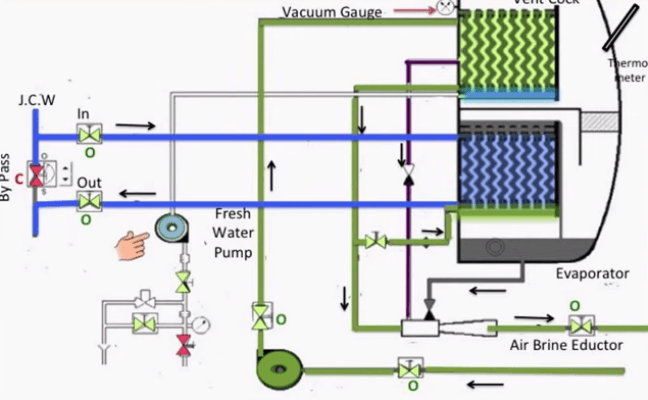

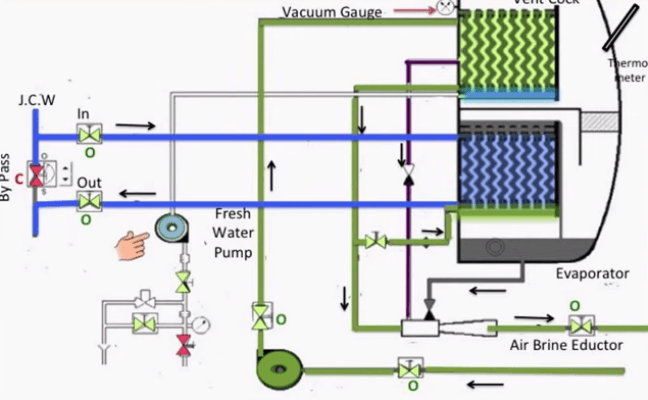

How Fresh Water Is Generated on a Ship: Step by Step Working Explanation

Most ships use the evaporator type fresh water generator. Let me break the process down in a simple way, so even a junior engineer can imagine it clearly.

1. Using Heat from the Main Engine Jackets

The main engine generates a lot of heat. To cool it, hot water circulates through the jacket. This water is around 70 degrees centigrade. Under normal atmospheric pressure, water boils at 100 degrees. But 70 degrees is not enough for evaporation.

So the FWG solves this problem by reducing pressure.

2. Creating a Vacuum Inside the Generator

The ejector pump removes air and creates a vacuum inside the chamber. When pressure drops, water boils at a lower temperature. Under a strong vacuum, seawater can evaporate even at 70 degrees.

This is why vacuum is the heart of the system.

3. Evaporation of Seawater

Inside the evaporator chamber, seawater is sprayed over heated plates. Because of the vacuum, the water quickly evaporates.

The salt and impurities remain behind.

4. Condensing the Vapor

The vapor moves into the next chamber, the condenser, where cold seawater cools it down. The vapor turns back into fresh water.

This water is called distillate.

5. Using a Salinometer to Check Quality

A salinometer constantly checks how salty the produced water is. A reading below 10 ppm is considered safe.

If salinity increases, the water is diverted to the drain automatically.

6. Fresh Water Pump Transfers Water to the Tank

The fresh water pump moves clean water into the main tanks for storage and usage around the ship.

All of this happens continuously during sailing, which gives the vessel a steady supply of usable water.

Components of a Fresh Water Generator Explained

1. Evaporator Chamber

Large cylindrical body where seawater is heated under vacuum so it evaporates at a lower temperature.

2. Condenser Chamber

Cools the vapor using seawater and converts it back into fresh water.

3. Ejector Pump

Creates the vacuum needed for evaporation. Works using seawater flow, not electricity.

4. Sea Water Pump

Feeds seawater into the evaporator and condenser. Common brands used in UAE fleets include:

- Gianneschi

- Jabsco

- Johnson

- Marco

5. Fresh Water Pump

Transfers distilled water to tanks.

6. Salinometer

Monitors the purity level and protects the tank from contamination.

7. Feed Water Treatment System

Prevents scale formation inside the plates.

8. Hot Water Inlet and Outlet Lines

Carry jacket cooling water to heat the evaporator.

How to Start a Fresh Water Generator on Ship: Full Step by Step Guide

Ship operators in the UAE often look for procedural content, since it helps junior crew. Below is a friendly but technical workflow.

Before Starting

- Check ship is not near shore or in polluted waters. Stay at least 20 nautical miles away.

- Engine rpm should be above 50 so jacket water is hot enough.

- Drain valve at bottom of generator must be closed.

- Suction and discharge valves of seawater pump should be open.

- Vacuum valve must be closed.

Starting Process

- Start the seawater pump and check pressure, usually around 3 to 4 bars.

- Wait about 10 minutes for vacuum to reach roughly 90 percent.

- Open feed treatment water slowly.

- Open jacket water outlet first, then inlet. Increase flow gradually.

- Watch boiling temperature rise and vacuum drop slightly to around 85 percent.

- Open fresh water pump line to drain.

- Switch on the salinometer.

- Start the fresh water pump and taste the drain water.

- Once salinity is good, open the tank line and close the drain.

After Stabilizing

- Monitor salinity

- Check vacuum levels

- Ensure steady distillate flow

How to Stop the Fresh Water Generator

Stopping is simpler.

- Close jacket water inlet then outlet.

- Close feed water treatment supply.

- Stop the fresh water pump.

- Switch off salinometer.

- Stop the seawater pump.

- Open vacuum valve.

- Close seawater suction and overboard valves if needed.

Reverse Osmosis vs Evaporator Method: Which Is Better?

| Feature | Evaporator FWG | Reverse Osmosis |

|---|---|---|

| Heat Source | Uses engine jacket water | Uses high pressure pump |

| Energy Cost | Relatively low | High consumption |

| Maintenance | Low to moderate | High, membranes need replacement |

| Common On | Cargo ships, tankers, OSVs | Passenger vessels, yachts |

| Water Quality | Very pure | Good but depends on membrane condition |

| Cost | Lower initial cost | Higher initial cost |

For most UAE merchant vessels, evaporators remain the preferred choice.

Common Problems in Fresh Water Generators and How to Fix Them

1. Vacuum Not Building

Possible reasons:

- Ejector nozzle clogged

- Air leak in system

- Sea water pump pressure too low

2. High Salinity Reading

Causes:

- Leaking condenser tubes

- Scale formation on plates

- Pump pressure fluctuation

3. Low Distillate Production

Usually happens due to:

- Low jacket water temperature

- Fouled heat plates

- Poor seawater flow

4. Bad Smell in Water

Often caused by:

- Dirty tank

- Bio growth in pipelines

- Faulty sterilizer

Maintenance Checklist for Fresh Water Generators

A practical checklist helps the crew.

Daily Checks

- Salinity level

- Vacuum gauge reading

- Water production rate

- Sea water pump pressure

Weekly Checks

- Clean strainer

- Inspect heater plates

- Check ejector operation

Monthly Checks

- Descale the plates

- Inspect condenser tubes

- Check salinometer calibration

Yearly Checks

- Replace seals

- Pressure test condenser

- Overhaul pumps

Fresh Water Systems on Ship: Beyond the FWG Setup

Fresh Water Tanks

Usually coated to prevent contamination and built for harsh marine conditions.

Fresh Water Pumps

Brands supplied by Amazon Blu Ship Supplies:

- Gianneschi Pumps

- Johnson Pumps

- Jabsco Pumps

- Marco Pumps

- Rule Pumps

These are used for distribution across cabins, galley, deck lines, and machinery areas.

Water Purifiers and UV Sterilizers

Added for safety and compliance with UAE port requirements.

Piping, Valves, and Sensors

All should be corrosion resistant and easy to access for maintenance.

Monitoring and Automation

Modern ships use IoT based systems to track:

- Water level

- Pressure

- Salinity

- Pump performance

How Amazon Blu Ship Supplies Supports Fresh Water Systems for UAE Fleets

Amazon Blu Ship Supplies is a trusted marine equipment provider in the region. With a full range of fresh water generator parts and system components, operators get both reliability and technical support.

What We Supply

- Marine fresh water pumps

- Desalination and RO units

- Pump spares and seals

- Valves, strainers, and fittings

- Heat exchanger parts

- Salinometers

- Water treatment chemicals

Why UAE Clients Prefer Our Support

- Fast delivery across all UAE ports

- Genuine branded marine components

- Technical assistance for installation

- Help with system troubleshooting

- Stock availability for emergency spares

Conclusion

A fresh water generator is essential for any ship sailing long distances, and understanding how it works helps the crew operate it safely and efficiently. With a clear understanding of evaporation under vacuum, system components, startup steps, shutdown workflow, and troubleshooting, marine engineers can maintain a stable supply of clean water onboard.

With reliable pumps, spares, and technical support from Amazon Blu Ship Supplies, UAE vessel operators can run a dependable fresh water system that meets modern maritime standards.