Description

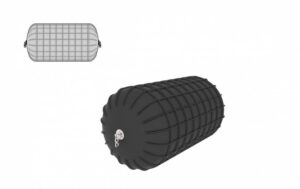

YOKAHOMA Pneumatic fenders with tire net

The tire net are the most common used pneumatic fenders and equipped with a so-called “netting”. The “netting” consists of car/truck tires placed with horizontal and vertical chains as a net to the fender (also available with aircraft tires). The tire net adds extra protection to the fender body. At each end the chains are fastened to a flange and towing ring with shackles. The horizontal and vertical chains, the towing ring, shackles and swivel are galvanised to prevent corrosion. The chains are covered by rubber sleeves to prevent damage to the skip. As an option the towing ring, flange and swivel are also available in stainless steel. All Pneumatic net type fenders come with an internal pressure of 0.5 Bar. All dimensions can be produced and supplied with 0.8 internal pressure.

YOUKAHOMA Pneumatic fenders sling

The Pneumatic fender sling is basically the same fender, but without the “netting”. The sling type Pneumatic fenders have a special outer rubber double-layered cover, which consists of a single cover and an extra tyre cord layer, resulting in better resistance to operational damages. At each end of the sling type fender, a flange with shackle and swivel is mounted to which a chain or cable can be attached.

All Pneumatic sling type fenders come – and are on stock – with an internal pressure of 0.5 Bar. All dimensions can be produced and supplied with 0.8 internal pressure.

YOKAHOMA Pneumatic fenders ribbed

The Pneumatic ribbed fender is a lighter and less bulky rubber protector than the standard fender with tire net. The ribbed type has reinforcements as a sort of rib cage integrated into the Pneumatic fender. At each end of the ribbed type fender, a flange with shackle and swivel is mounted to which a chain or cable can be attached.

The Pneumatic ribbed fender will be a superb alternative when weight and flexibility in use are the main objectives. Our Pneumatic ribbed fender is made of high European quality rubber and has been ISO approved. Discover the features for the Pneumatic ribbed fender below, as well as more information on the ISO approval. Our office is located near the port of Rotterdam in the Netherlands. We ensure fast worldwide shipping.

Foam filled fenders PU

Polyurethane is increasingly used for the production of fenders as it provides a number of advantages over rubber. PU is extremely durable, it has lower friction and lower specific gravity. The material is also non-marking and it can be produced in various striking colours.

Besides fenders that are completely made of polyurethane, this material can also be combined with foam.

Types and processing

Polyurethane foam fenders have a skin made from PU and they are filled with foam. The skin is wear-resistant and it has low frictional resistance. The core has a high density and thus readily absorbs energy.

The advantage of foam fenders is that the reaction to compression is mucg lower. This type of fender is used on fast moving vessels on which weight also plays an important part. Fixed length PU fenders are produced through mould casting

Applications

Polyurethane and foam fenders can be used for:

– Tugboats

– Catamarans

– Workboats

– Rescue boats

– Pilot boats

Reviews

There are no reviews yet.